52

World Cement

North America 2019

to close through a standing column of material, if

necessary.

The round-to-square transition above the

maintenance gate contains a ANSI #150 pattern

to connect to the silo and was extended to take

up some of the extra space that existed within the

overall stack up.

Below the maintenance gate is a

Vortex Titan Slide Gate. The gate is pneumatically

actuated by an air cylinder that is equipped with

a threaded rod stop. The rod can be manually

adjusted to limit the opening stroke of the blade.

This feature is used to control the flow of material

to the rotary feeder below.

The Titan Slide Gate is equipped with bonnet

seals that allow the external replacement of the

seals, without having to remove the gate from

place. Modifications were made to address

the fineness of the material handled. The gate

contains a smoother 304 stainless steel blade

and secondary silicone rubber bonnet seal.

Additionally, the bonnet area is air purged to

discourage the accumulation of fine material.

Inlet and outlet transitions with flanges make up

for the remaining space between the maintenance

gate and the plug valve.

Because the telescoping spout was mounted to

the flooring, it is easily accessible for inspection or

maintenance. The company’s spouts are equipped

with a four cable hoist system. This means that,

if a cable should wear or break, the spout will

still be operational until maintenance finds time

to replace it. Vortex’s CNC-machined pulleys,

with radius edges and precision cable grooves,

significantly reduce cable wear. The lifting cables

offer a 10 year cable warranty. A material handling

fan effectively removes dust, created during the

loading process, to where dust collectors are

located at the top of the silo.

Conclusion

Ball Sales was involved with this project

from inception to completion. Because of an

opportunity the customer envisioned, area power

plants now have a broader market for selling

the flyash byproduct, local concrete producers

are able to access a much needed ingredient at

a more reasonable price, and a new business

unit was established. As a result of Ball Sales’

knowledge and expertise, the proper equipment

was selected and installed in this particular

application. The result is a win win for flyash and

the cement industry.

About the author

Kevin Peterson is the Business Development Director

for Vortex’s Titan Products Division. He has created

and shared many articles that address material

handling issues for various industries that deal with

the handling of dry bulk materials.

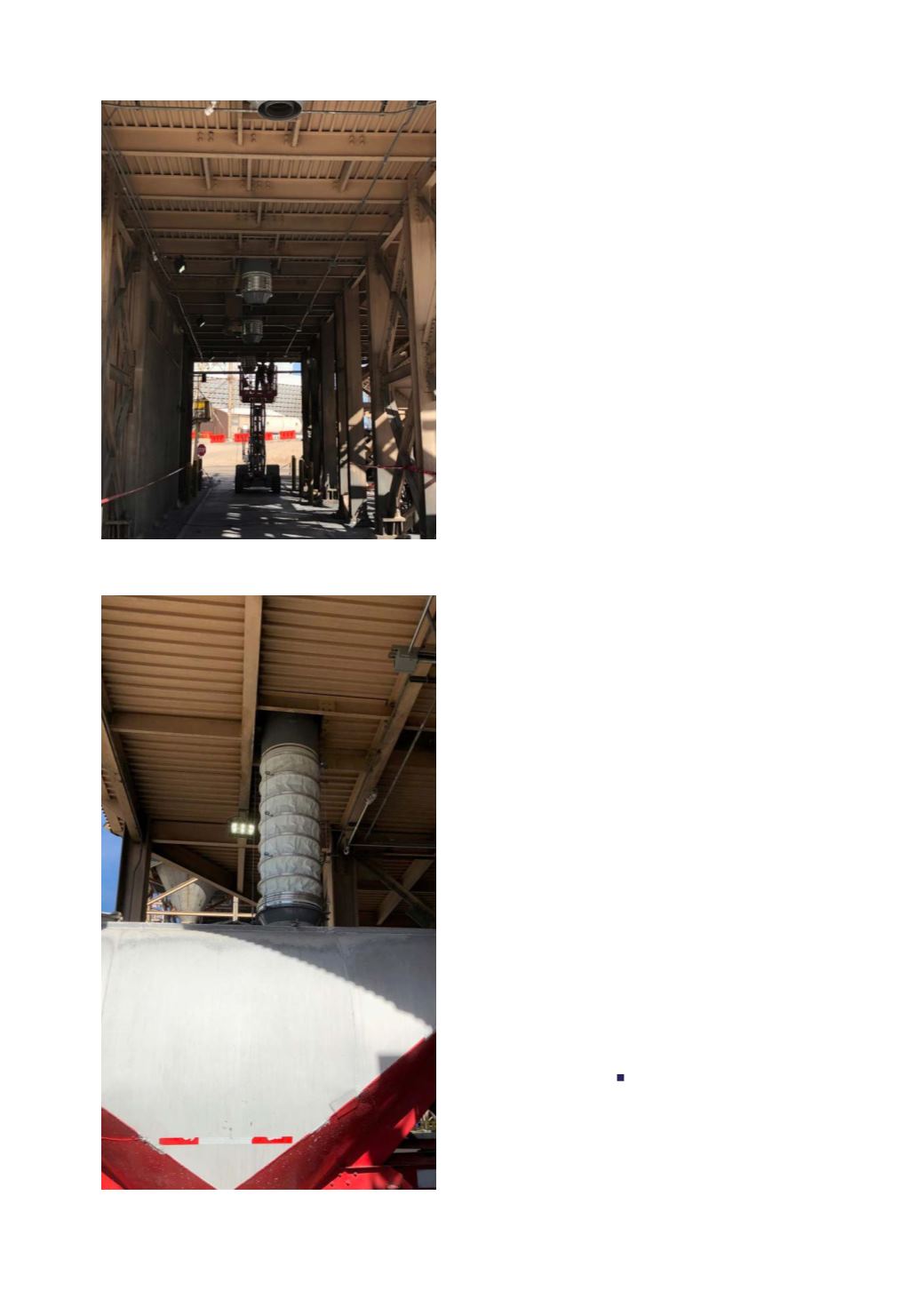

Telescoping portion of the loading spout, as

seen from truck loading.

Loading flyash in a non-dusty environment.