54

World Cement

North America 2019

loads in the cement-making process,

high‑efficiency backward curved or backward

inclined blade designs became preferred

for their more efficient operation, reduction

of power costs, and, in turn, cost/tonne

of product produced. These BIC and BIF

designs became popular in new installations;

in addition, many existing installations were

retrofitted with these high efficiency designs.

Through testing and actual operation history,

it was discovered that a backward inclined

curved blade, streamlined for laminar flow

across the blade, would reduce the hard,

layered-type of buildup on the top of the blade.

By matching the blade to the streamlines of

the flow, the impact of the material entrained

in the gas stream can be minimised on the top

of the blade, if not eliminated. However, just

by the nature of the shape of the blade, the

concave curvature on the bottom side of the

blade becomes subject to buildup with a soft,

powdery material.

Dangers of buildup

Having material buildup on either side of

the blade is undesirable. During operation,

the buildup on the blades normally occurs

non‑symmetrically, leading to a heavy spot

on the rotor and creating an imbalanced

condition, potentially damaging vibration at

the bearings. In addition, the buildup will

eventually begin to shed unevenly off the

blades; again, creating a heavy spot on the

rotor and leading to vibration. At a defined

setpoint level of vibration, to prevent damage

to the bearings and the shaft journals the fan

is normally shut down and the rotor cleaned.

This downtime is not only inconvenient but is

also extremely costly.

A solution

To address this problem, ProcessBarron has

developed a new system that will minimise, or

even eliminate this buildup of soft material on

the bottom side of a backward curved blade.

This extends the operating time between these

shutdown events, which are required to clean

the preheater ID fan rotor. Using compressed

air with high-energy nozzles, the buildup is

continuously swept off the blade with timed

blasts or puffs of compressed air released

instantaneously by a fast-acting, high-volume

valve (sometimes referred in the industry as

a poppet valve). It is a simple, easy to install,

and cost-effective system. The concept

is similar to the air cannons used to keep

material from bridging and limiting production

rate commonly found on the pre-calciner.

A compressed air system consists of a

cleaning lance, a compressed air reservoir

or accumulator tank, and a fast-acting,

high‑volume valve or poppet valve. The

cleaning lance has a row of nozzles installed

on it that are positioned close to the leading

edge of the rotor blades. On a single-inlet

fan design, one lance is required, whereas

on a double-inlet fan two lances are needed.

The lances are designed to be adjustable so

that the best angle of attack for the pulse of

compressed air can be made relative to the

angle of the backward curved blade. The

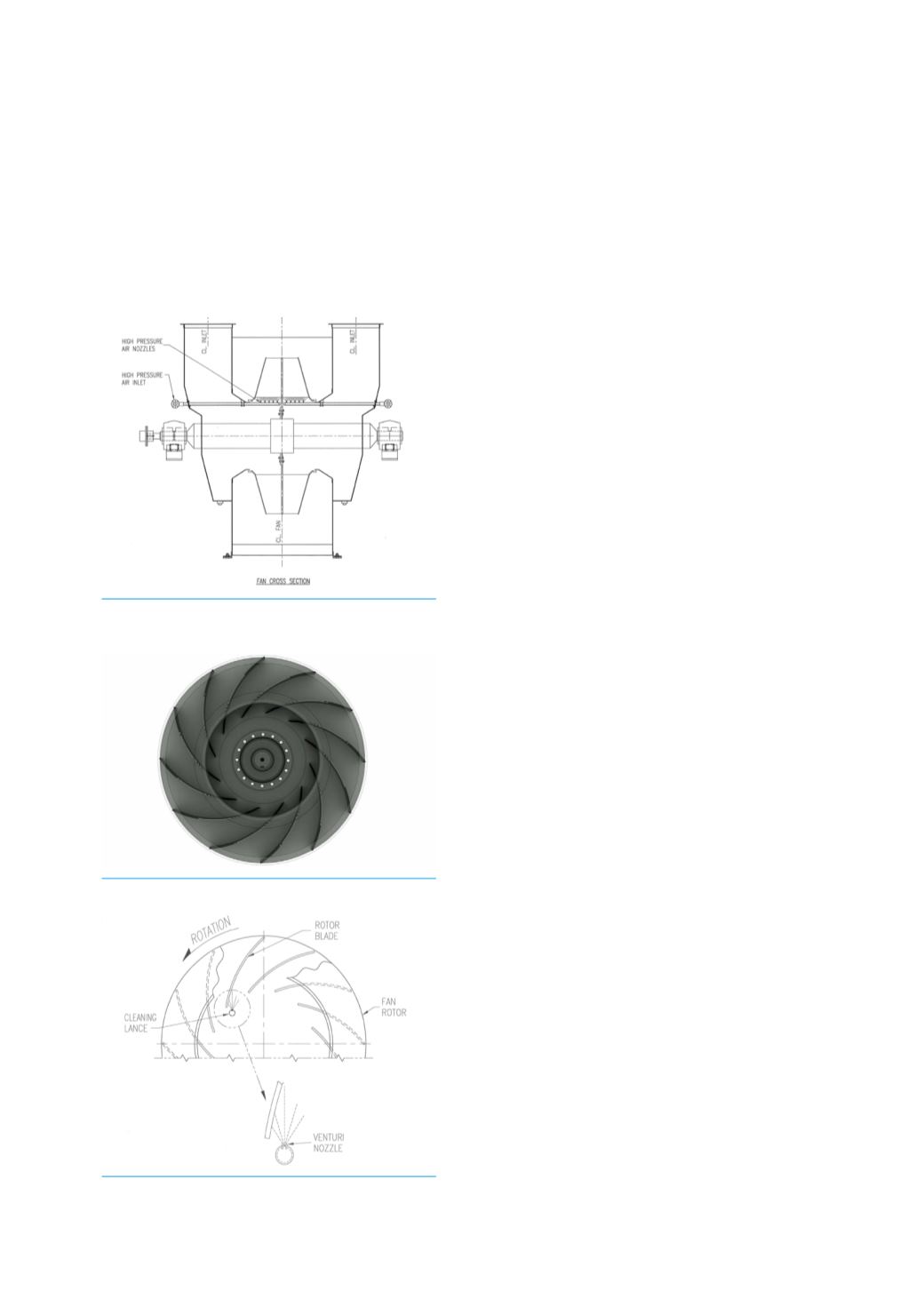

Cross-sectional view of fan with compressed air

lances.

Elevation of backward curved blade design.

Elevation of lance with nozzles and spray

pattern.