55

North America 2019

World Cement

length and number of nozzles varies according

to the size and width of the fan rotor.

The compressed air used for the cleaning is

stored in an accumulator tank. The tank size

is directly related to the size of the rotor to

be cleaned; the larger the rotor, the larger the

area to be cleaned and, in turn, the larger the

amount of reserved compressed air needed.

At defined time intervals, the fast-acting,

high-volume valve, opening in milliseconds

when triggered, will engage, allowing for a

high-volume, high‑pressure blast of air into

the cleaning lance. This is then distributed

on the blade surface by the array of nozzles.

The frequency of the firing of this valve

is dependent on the service and the dust

loading.

Considerations for the plant

The utility requirements normally provided by

the plant are a source of compressed air for

cleaning, a source of filtered compressed

air for instrumentation, a 120 V/3 PH/60 Hz

energy source, and a controlling mechanism,

such as a stand alone programmable logic

control device or a connection with logic for a

digital control system.

The volumetric requirements of compressed

air can be taxing to a plant’s normal supply

of compressed air. Dependent on the size of

the fan, the volumetric flowrate rate for the

system would range from 2 actual ft

3

/min. to

5 actual ft

3

/min. at 100 psi maximum pressure.

At this capacity rate, the system can be fired as

often as every 15 min. if needed. Using higher

pressures could result in rotor damage over

time. If this compressed air need is overbearing

to the current compressed air system, adding

a stand alone air compressor for the supply

source is a simple solution.

How it works

The time that the valve is open is relatively

short, lasting for only a few seconds. The

initial blast is where the most effective

cleaning occurs. Given that these fans

normally operate at 900 RPM or 1200 RPM,

even with a blast that is a few seconds long,

each blade will be contacted multiple times

(45 to 60 times) on each cleaning cycle. By

minimising the duration of the open valve time,

the accumulator tank still maintains a certain

degree of pressure, making the time and cost

to refill less.

Leaving the cleaning compressed air unfiltered

and moist can be an advantage. These moisture

droplets, when exposed to the hot gas stream,

will flash and immediately expand. The expansion

rate for water to steam at atmospheric pressure

is approximately 1600 to 1. This rapid expansion

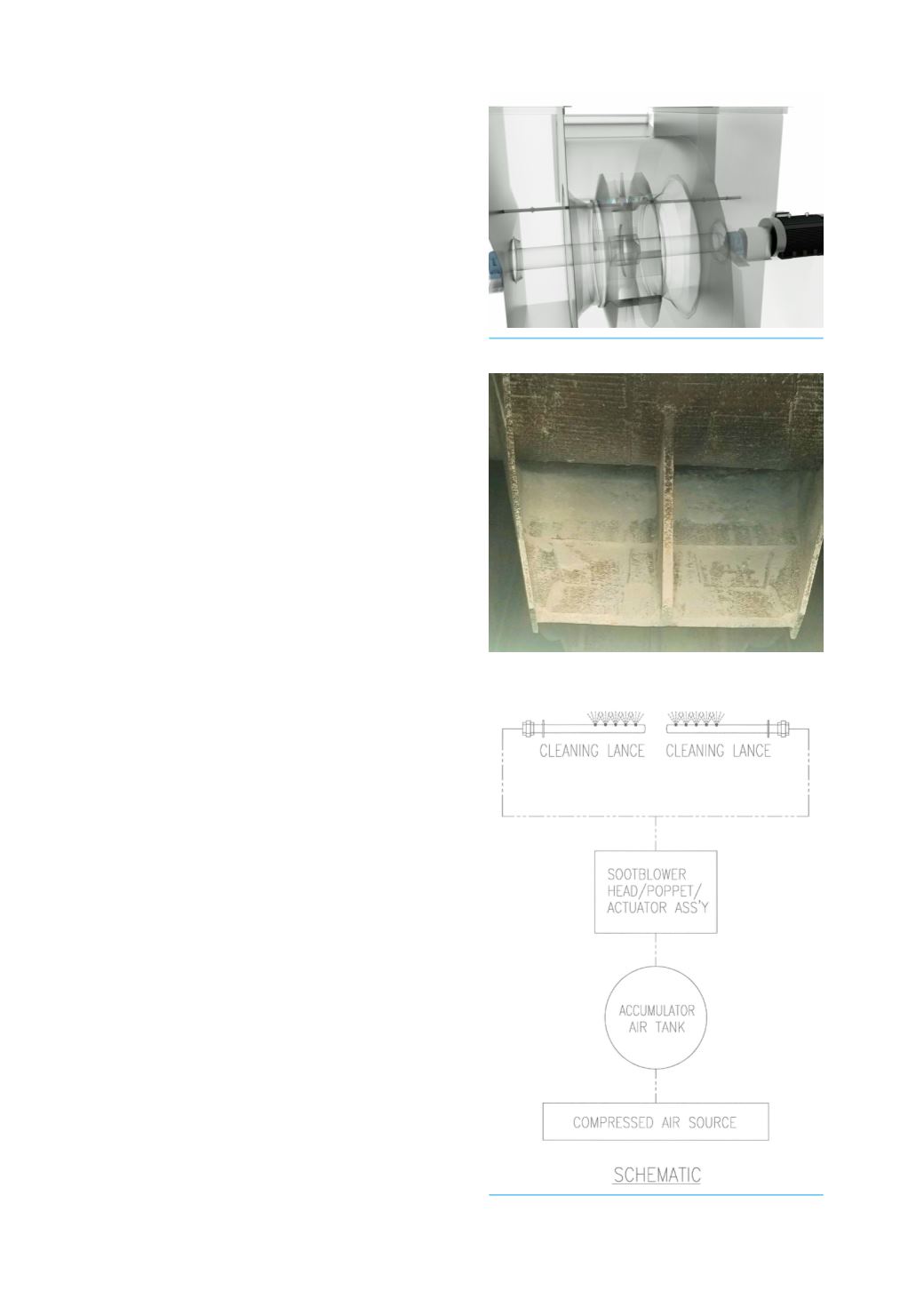

Rendering of the compressed air system.

Another example of buildup on a backward

curved blade.

Schematic of CAC system.