40

World Cement

North America 2019

Application review

There are many unique applications implemented

in a cement plant. However, the science utilised to

manufacture portland cement has remained largely

unchanged for many years. With that said, many

engineered applications, no matter the age or location

of the cement plant, are largely similar. One can easily

identify slow speed, small to medium horsepower,

and low voltage applications that require head drives.

These include bulk material handling conveyors,

clinker drag conveyors, screw conveyors, and bucket

elevators. These four specific applications can

be found in every cement plant. They encompass

analogous design parameters.

An existing important bucket elevator, operating

at 28 RPM, has an aging gear reducer with the

associated design parameters: 64:1 speed reduction

ratio, foot-mounted, 72.3 kW (97 hp.) mechanical

rating, double reduction offset parallel, and shrink

disc mount to a 150 mm head shaft. A foot‑mounted

Baldor‑Reliance

®

induction motor with #ECP4410T-4,

125 hp. (93 kW), 0.85 power factor, NEMA frame

444T, 4 pole, 3 ph/60 Hz/460 V powers the head

drive. The motor and gear reducer are connected via

a high-speed flexible coupling.

Plant control systems indicate that the motor is

well oversized for the application and operates, on

average, at 50% of full load amperage. By locating the

motor manufacturer’s performance curve (Figure 2),

one can determine that at 50% full load amperage (or

72 amps when FLA = 144 amps), the interpolated

required working horsepower will be approximately

46 hp. (34.3 kW).

The combined powertrain, though well mismatched

by conventional engineering practices, has performed

admirably for the last 20 years, with the exception of

the two-fold gear reducer rebuilds and intermittent

bearing and seal replacements. The reducer, now

obsolete, catastrophically fails, causing an application

outage and lost time production. What should the

cement plant do with no application critical auxiliary

plan in place? With a change of paradigm and reverse

engineering in order to verify form, fit, and functionality,

a timely replacement solution does exist.

Selecting an induction motor

A motor achieves its highest efficiency when

operated at between 75% and 80% below full load

horsepower. Additionally, a motor utilises its peak

power factor when operated at full load or above.

Although it is not uncommon to operate a motor

above its nameplate horsepower, this practice is

not recommended due to the introduction of high

temperature to the motor insulation and bearings.

Consequentially, a reduction in the optimal service life

of the equipment will result.

The original motor design was 125 hp. (93 kW)

and the working horsepower required to move the

bucket elevator fully loaded is 46 hp. (34.3 kW). Since

a 46 hp. motor is not available, there are two choices

moving forward: a 60 hp. (44.8 kW) motor or a 75 hp.

(56 kW) motor. Utilising a 60 hp. induction motor

affords that the motor will be approximately 77%

loaded. Selecting a 75 hp. motor indicates a loading

of 61.3%.

In order to make a smart decision for selecting

the correct motor, it is important to consider the

additional torque required for the worst case scenario:

a fully‑loaded bucket elevator that is stopped. To

account for this condition, motor size is optimised

when looking at the locked rotor point of the design

B speed‑torque performance curve. Respectively, for

a 60 hp. and 75 hp. motor, the locked rotor torque

delivered is between 181% and 190% above full

load torque, per the typical manufacturer’s motor

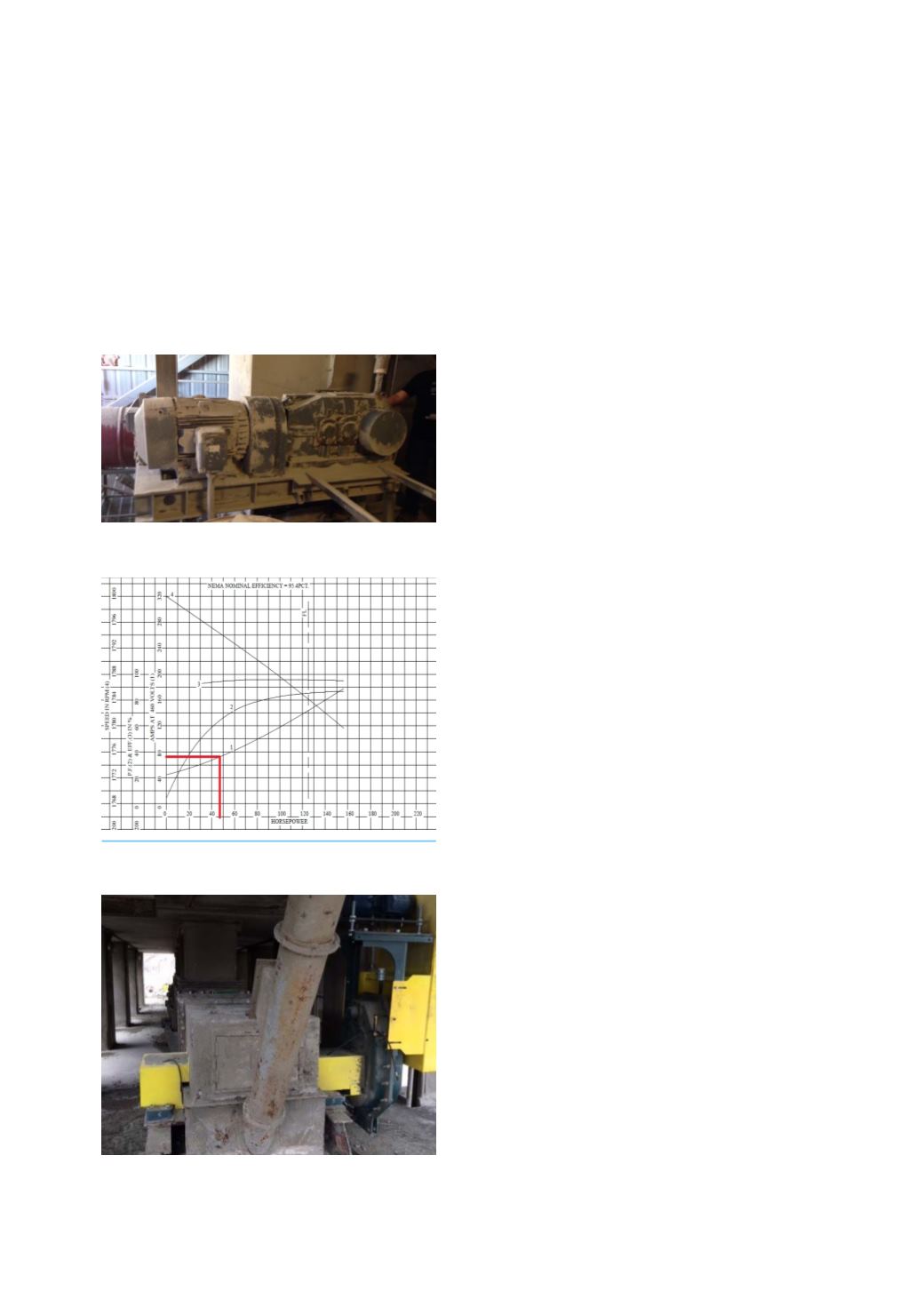

Figure 1. An aged gear reducer was a solid

piece of equipment in its day.

Figure 2. A typical motor performance curve, in

this case a Baldor-Reliance

®

#ECP4410T-4.

Figure 3. A typical Dodge

®

Torque-Arm

®

II

powertrain. There are over 2 million of these

units in service.