46

World Cement

North America 2019

The more manpower, equipment, and

expertise needed onsite, the more costly an

inspection can become. This also depends on

how many silos are inspected. Is just one being

inspected or is it six? And for how many days

will the experts be onsite? Will it be one day or

two weeks?

Unfortunately, some customers have let

silo inspections lapse. The result is dozens

or hundreds of silos that must be inspected,

usually at a great cost.

It is suggested that companies plan a rotating

annual inspection programme and configure

that programme so that the problem silos are

observed and inspected more frequently. More

structurally sound silos can go longer without

inspection. In this way, the most economical

programme can be designed and potential

issues caught before they become major

structural or catastrophic problems.

Inspection specialisation

How silos differ from more common structures

is usually related to the unusual load

configurations that must be taken into account,

such as gravity and horizontal loads.

Silos are designed to hold vertical loads

from gravity forces. The design must withstand

internal pressures from materials that are

statically stored, but they must also resist

pressures from materials flowing through the

silo, as well as environmental conditions.

From the start, the key to protecting a silo

is based on proper design and construction.

General engineers are not typically experienced

in the pressure-loading design of silos. Many

inspection reports include cases where

a company has hired a local engineer, a

silo cleaning company (one that only does

cleaning), or a company that is on the periphery

of silo design and construction. However, the

inspection reports from these companies are

expensive and do not address the important

issues that are already understood by silo

contractors. In more than 60% of these cases,

observations provided by those not specialising

in silo construction are not credible and often

require re-inspection. They typically do not

address the true root cause of a problem and

often they do not know the best way to fix what

they find. For example, one customer spent

US$100 000 on an inspection, before being

provided with a report that had no usable

information to help design a repair.

Preventative maintenance

After the periodic inspection of cement silos

is established, the keys to maintaining healthy

and sound silos are cleaning and maintenance.

These keep the cement flowing through the

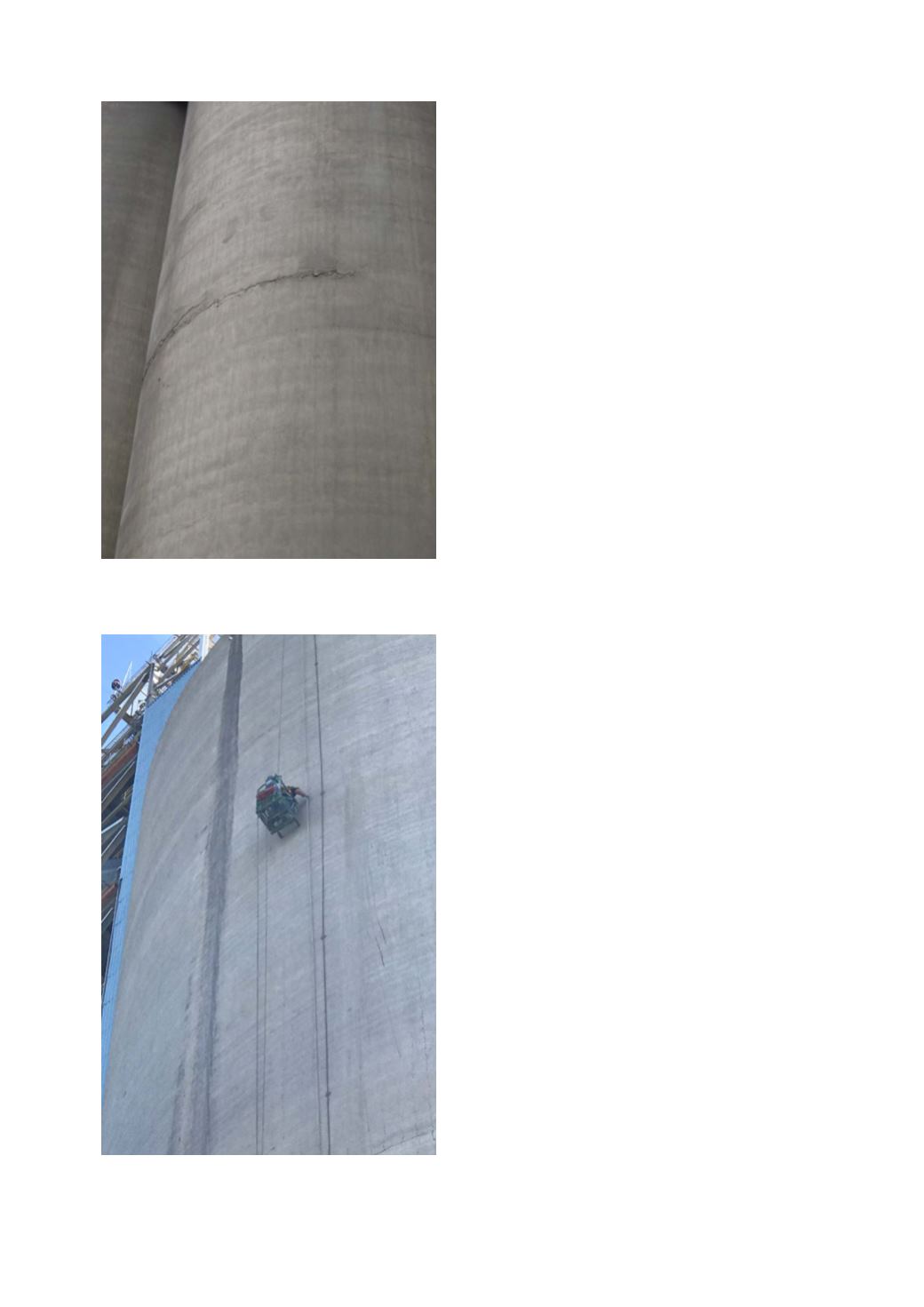

A thorough inspection of the exterior silo walls

includes visual and other techniques to detect

concealed weaknesses.

Lateral interior loads can stress the silo wall.

Here, a large crack will be closely evaluated

and a repair plan presented to the owner.